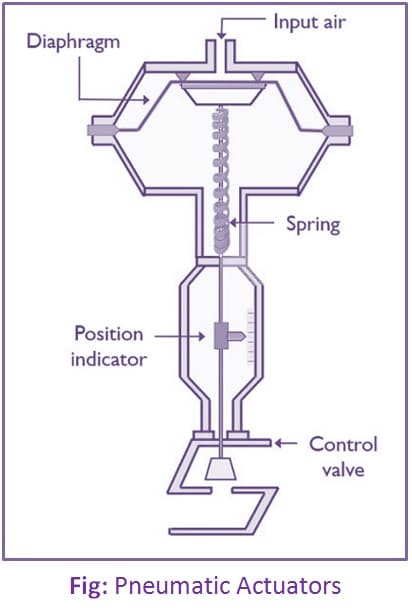

Pneumatic Actuators:

Pneumatic actuator is a devices that convert the energy of compressed air or gas into a mechanical motion that regulates one or more final control elements. It converts the energy of compressed air or gas into a mechanical motion that regulates one or more final control elements.

Advantages of Pneumatic Actuators:

1. The benefits of pneumatic actuators come from their simplicity. Most pneumatic aluminum actuators have a maximum pressure rating of 150 psi with bore sizes ranging from 1/2 to 8 in, which translate into approximately 30-7500 lb of force. Steel actuators have a maximum pressure rating of 250 psi with bore sizes ranging from 1/2 to 14 in, and they generate forces ranging from 50 to 38465 lbf.

2. Pneumatic actuators generate precise linear motion by providing accuracy.

3. Pneumatic actuators typical applications involve areas of extreme temperature. A typical temperature range is -40°F – 250°F. In terms of safety and inspection by using air. Pneumatic actuators avoid using hazardous materials. They meet explosion protection and machine safety requirements because they create no magnetic interference due to their lack of motors.

4. In recent years, pneumatic has been many advances in miniaturization, materials, and integration with electronics and condition monitoring. The cost of pneumatic actuators is low compared to other actuators.

Disadvantages of Pneumatic Actuators:

1. Pressure losses and air compressibility make pneumatic less efficient than other linear-motion methods. Compressor and air delivery limitations mean that operations at lower pressure will have lower forces and slower speeds. A compressor must run continually operating pressure even if nothing is moving.

2. To be truly efficient, pneumatic actuators must be sized for a specific job. Hence, they can’t be used for other applications. Accurate control and efficiency requires proportional regulators and valves, but this raise the costs and complexity.

3. Even though the air is easily available, it can be contaminated by oil or lubrication, leading to downtime and maintenance. Companies still have to pay for compressed air, making it a consumable and the compressor and lines are another maintenance issue.